CATEGORIES

- SONIC ART CABLE RANGE->

- SONIC ART "ITSaRACKIT" SHELVING

- REGA TONEARMS, UPGRADES & WIRING->

- TURNTABLE ACCESORIES->

- ORIGIN LIVE UK->

- ORACLE AUDIO CANADA->

- AUDIO TECHNICA TURNTABLES

- PHONO CARTRIDGES->

- CEC AUDIO JAPAN->

- AUDIOLAB UK->

- PRO-JECT AUDIO->

- SONIC ART POWER SUPPLIES

- SONIC ART FABRICATION SERVICES->

- AUDIOPHILE VINYL & CD's->

- VACUUM TUBES->

- REPLACEMENT REMOTE HANDSETS!

- DIY AUDIO COMPONENTS->

- CLEARANCE, DEMOS, TRADE-INS!

- Specials ...

REVIEWS & TECHNOLOGY

VTA EXPLAINED BY REGA

VERTICAL TRACKING

ANGLE

Reproduced From The Rega Book "A Vibration Measuring Machine"

The world of turntable design

is riddled with myths, all the more so since the turntable's vital role in

system sound quality was established during the 1970s. Obsessive consumers

often seem to suffer enormous (albeit quite unnecessary) angst over cartridge

and stylus alignment, making minute adjustments to tonearms and cartridges in

order to optimise the vertical tracking angle (VTA) and/ or stylus rake angle,

azimuth, and overhang.

Rega has measured the vertical tracking

angles of more than 100 different cartridge models, and has found that their

actual VTAs vary between 20 and 36 degrees (with downforce), and most fell

between 23 and 28 degrees. (Rega itself has opted for 27 degrees, without

downforce, and 23 degrees at normal downforce.) The overall figures may

therefore be up to 10 degrees greater than that required to meet the current

(and nominal) 20 degree disc-cutting standard. (In practice, reducing the VTA

of the cartridge cantilever to less than 23 degrees risks the rear of the

cartridge fouling the disc surface.)

Furthermore, talk to the

cutting engineers that are actually responsible for making the discs, and it's

clear that they pay very little attention to so-called cutting 'standards' .

One reason is simply because the VTA is defined by the mechanics of the cutter

head, and is not normally changed by the cutting engineer. It may also vary by

at least 7 degrees across a single disc, depending on frequency, cutting depth

and lacquer springback. (Indeed, the standard itself was changed from 1958's 15

degrees to 20 degrees in 1975.)

Enthusiasts' favourite way of changing VTA 1s to adjust the height of the arm

pillar, but a quick examination of the geometry involved clearly shows that a

0.5-inch variation in arm pillar height (probably the maximum possible in

practice) will only change the VTA by 3 degrees (±1.5 degrees). Crucially,

making the pillar adjustable in the first place is very undesirable from an

overall rigidity perspective, since this joint is the turntable/arm's core

reference point from which all system vibrations are measured.

Note that all formal disc-cutting

parameters in practice fall below 18 degrees, whereas arm/ cartridge replay

usually occurs above 24 degrees to avoid any risk of fouling the disc surface.

That fact alone means that fiddling around with VTA adjustment is entirely

futile. (In reality, the rear of the arm needs to be as close to the surface of

the disc as possible. Any adjustment upward can only increase the unavoidable

VTA inaccuracy.)

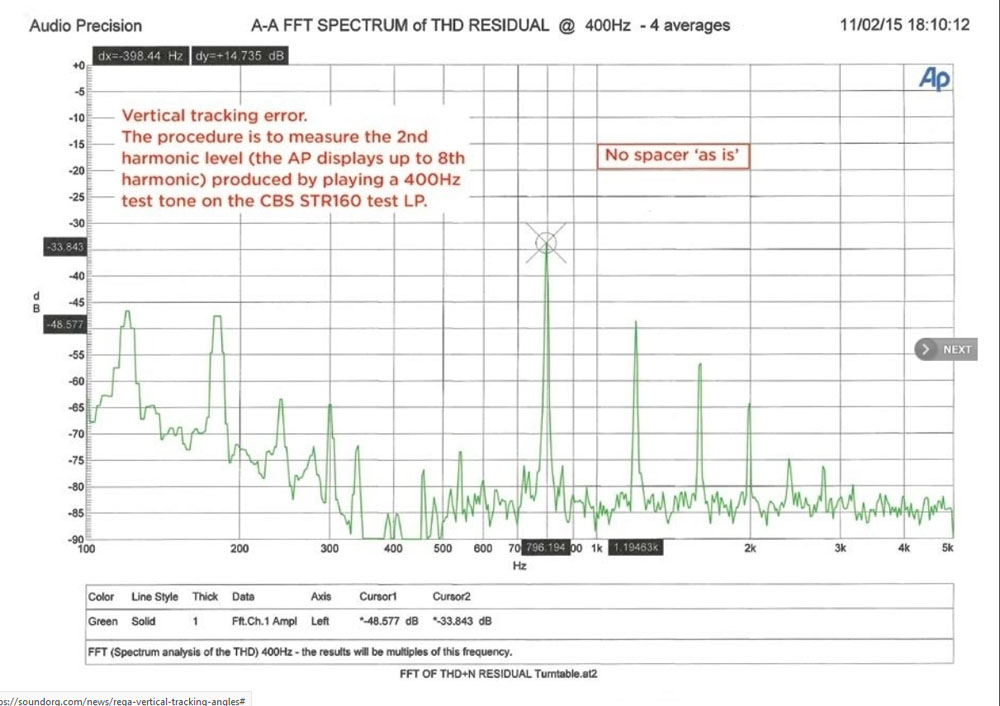

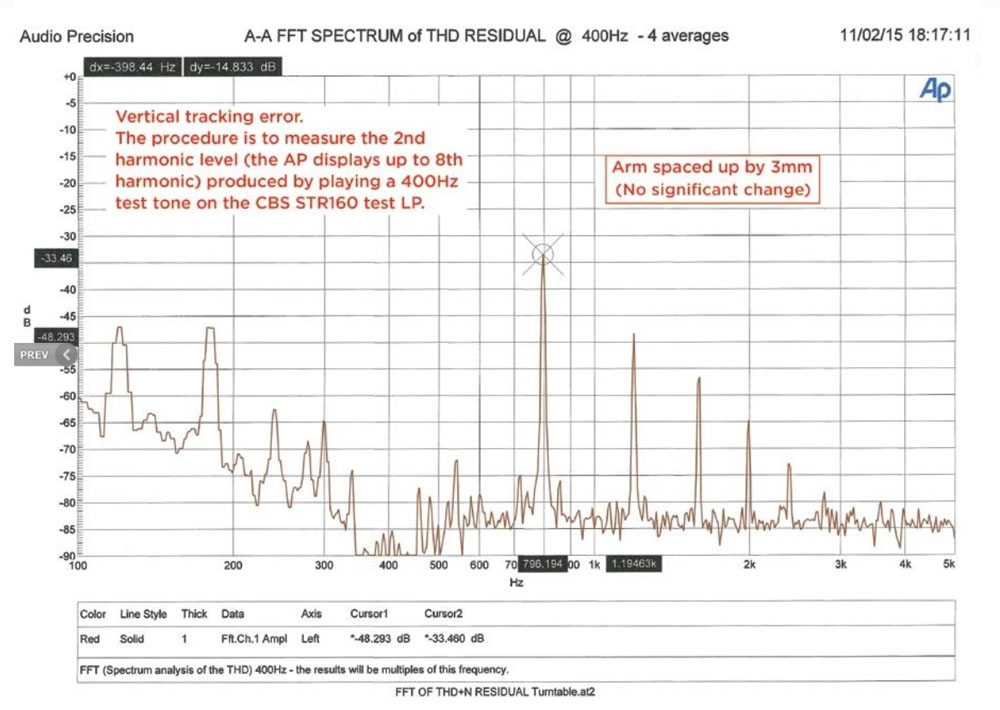

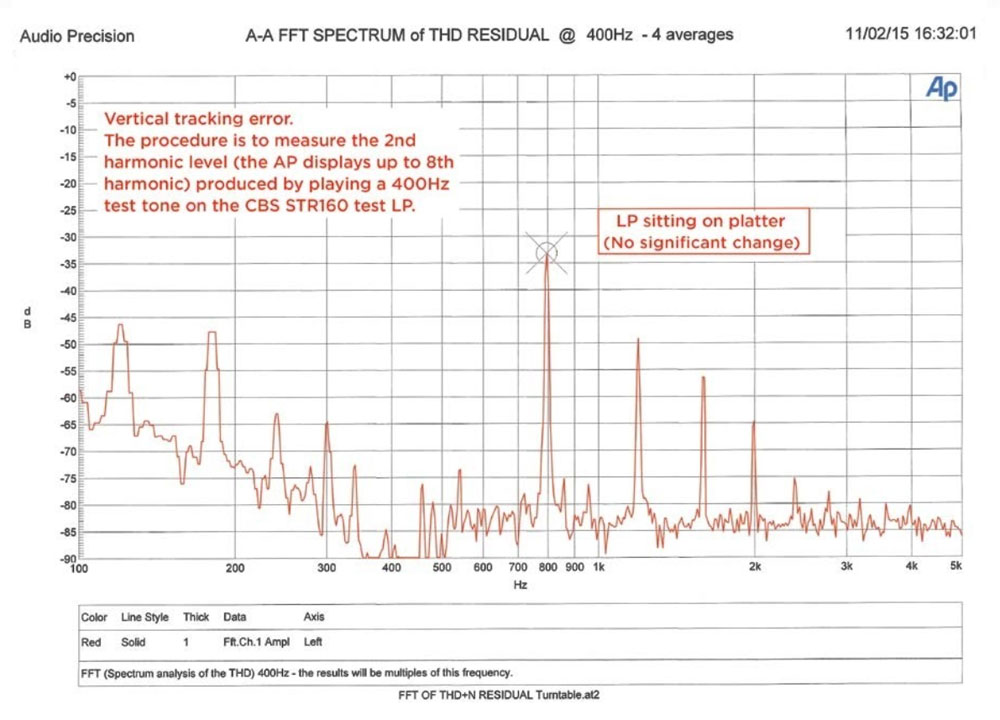

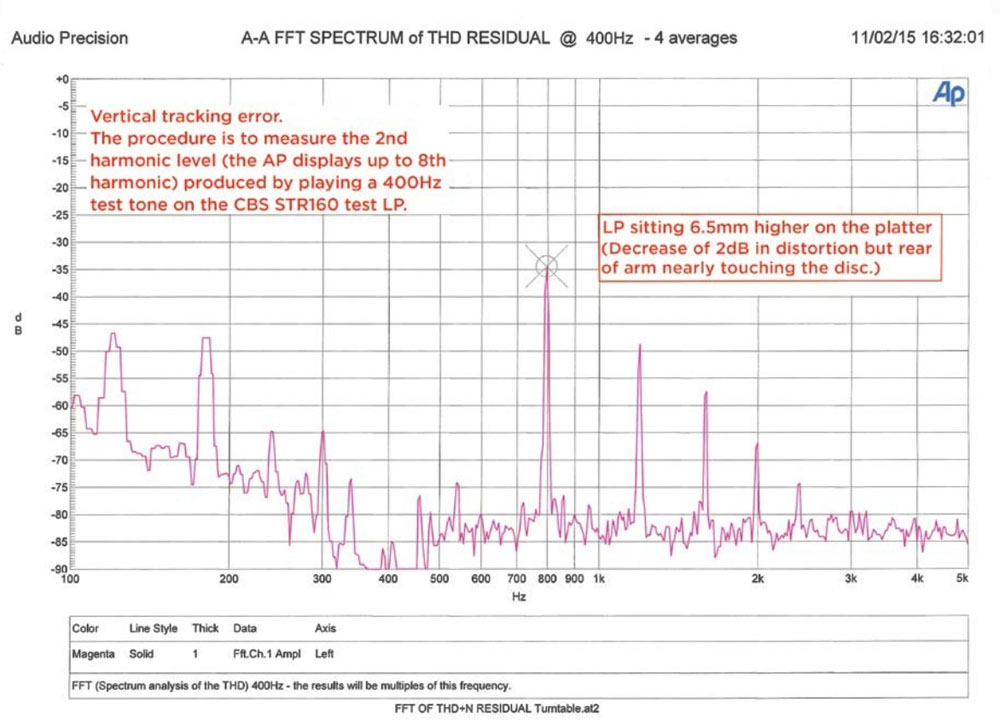

One method of measuring

distortion due to VTA variation is to use a test record (in this case the CBS

STR160 VTA test). A test tone of 400Hz is played and the second harmonic

distortion is measured at 800Hz.

Rega electronic design

engineer, Terry Bateman, carried out this test using audio precision test

equipment. The following four graphs show the test results as follows:

- The test record played on the standard Rega mat.

- The arm height increased by 3mm using a spacer.

- The test record played on the platter without a

mat.

- The test record raised off the platter by 6.5mm.

It can be seen that the graphs

show no significant change to the second harmonic distortion even though the

total effective change in the arm height is 9.5mm. Also note that the SRA is

changing as well as the VTA.